Olly Pedder, 33, started working for us nine years ago cleaning frying ranges. Now he is halfway through a three-year apprenticeship to become a fully qualified commercial catering gas engineer. Here, Olly shares a day in the life of a KFE apprentice

For one week out of eight, I attend a training centre in Stockport where a typical day can involve anything from carrying out practical work on fryers and ovens to checking we are hitting all the standards expected of us to sitting exams.

Recently we had a module on route planning, so getting to the customer at the right time for their trading hours, accounting for traffic and fuel stops – all the elements that make a good engineer.

Across the country

A typical day when I’m out with a KFE engineer can take me anywhere across the country, from Newcastle down to Cornwall, and it’s where I put theory into practice.

There are three types of jobs I can go on: breakdowns, which is fixing any problems with a range that on occasions may arise; servicing, which is the annual service that needs to be carried out once a year; and new installations, whether that’s a fish and chip shop that is replacing an existing frying range or a completely new site having a frying range put in.

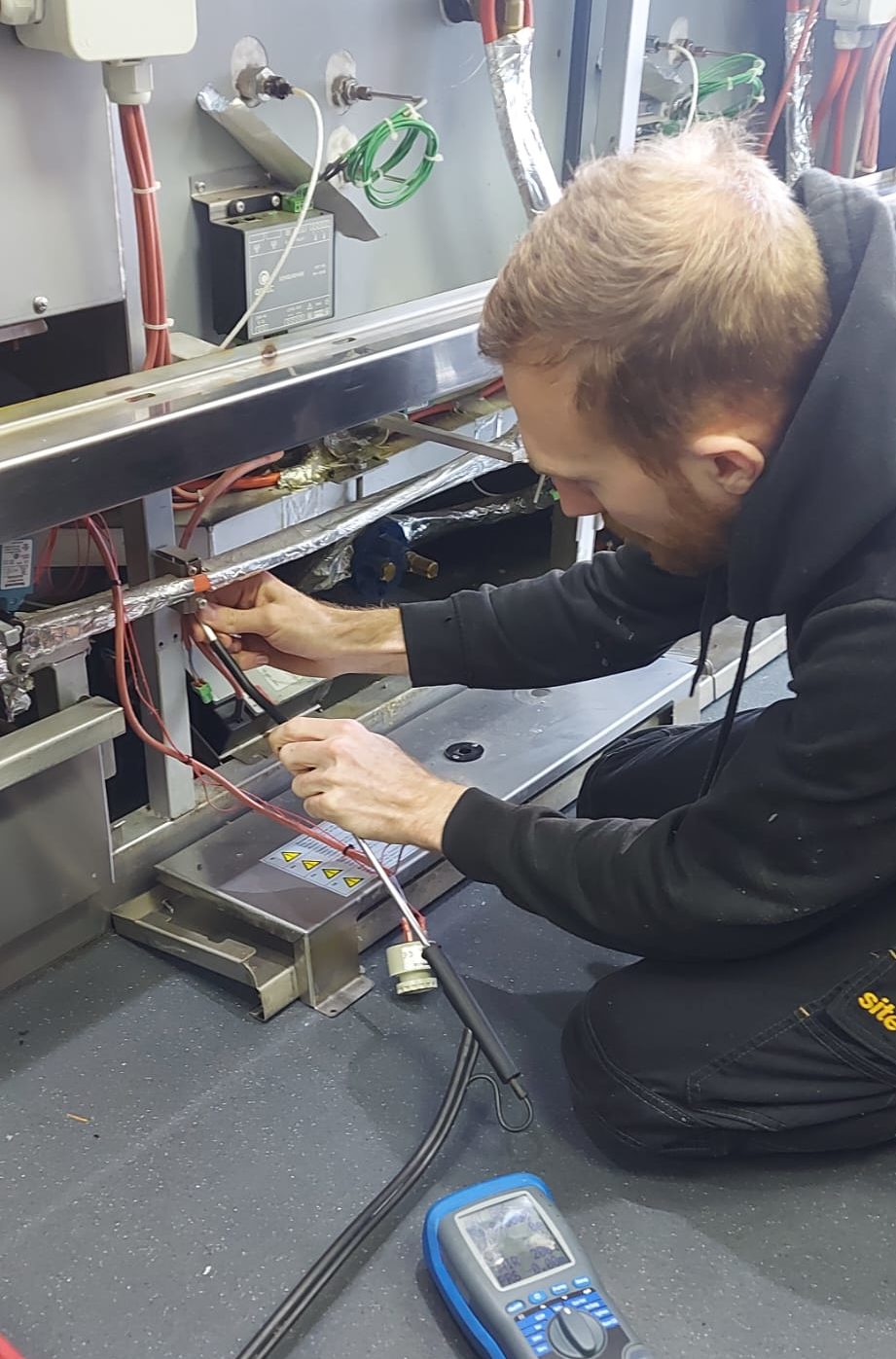

Whereas at the start of my apprenticeship it was a lot of shadowing, taking notes and asking questions, I’m now at a point where I have my own tools and testing equipment and the engineers let me do every part of a job. They continually monitor and assess me and on every job I attend I am with a qualified engineer.

Applying knowledge

On quite a few installs recently, I’ve planned out how the gas gets to the fryer, which involves applying my knowledge of the gas regulations. Is the gas going through any walls because, if it is, the pipes need certain sleeves? Is it away from water and trip hazards? What size of gas is needed as the regulations can be different? I’m constantly thinking, what is the safest route?

I get to cut the pipes and put all the bends together – but without soldering them – so the engineers can check it and say, yes, that’s perfect, that’s how I would do it, or they might suggest a better route.

Most days include two, sometimes three jobs, and that side of it I really enjoy too – speaking to all our customers and seeing the variations in how they fry, the different menus and prices, and especially the different styles of Kiremko frying ranges, from brand new ones with our touchscreen controllers to ones dating back 25 years!

Gaining a trade

I’m really appreciative of KFE for putting me forward for an apprenticeship and believing in me. I didn’t really have qualifications to speak of before so to get a qualification and become a Gas Safe engineer at the end of this is going to be great. I’ve gone from not knowing what I wanted to do or where I was going, to having a trade.

I’ve got a family and two young daughters to support so when I qualify in June 2024, that’s going to be the start of my career.

Our service department boasts 12 fully-qualified range engineers covering the whole of the UK, a service that remains unmatched by any other UK range manufacturer.